Ormskirk Council Offices West Lancashire

Building Surveyor, West Lancs Borough Council

“Shield from the offset were professional and attentive throughout the project. Despite the complexity of the works during the COVID19 lockdown, the removal was completed in a safe, controlled and timely manner. Ryan Lillis, Dan Edwards and the rest of the team met every challenge and extended themselves to ensure all our needs were met. To summarise, I would highly recommend Shield and would be more than happy to work with them on future projects”.

Asbestos Removal

Overview

Shield Asbestos Services, Warrington branch, completed some crucial removal works at Ormskirk Council Offices during lockdown.

The Council offices needed a new heating system installed throughout the building. The duct space had extensive contamination which rendered the space inaccessible and Shield were required to undertake complete removal works of all the pipe lagging and conduct a full environmental clean of the duct, to allow for further works to be carried out.

The offices remained open and functional during the works, with both Council staff as well as sub-contractors carrying out other works. As a result, we were requested to complete enclosure 1 as a priority, to allow the heating engineers to follow and begin to map out the heating system.

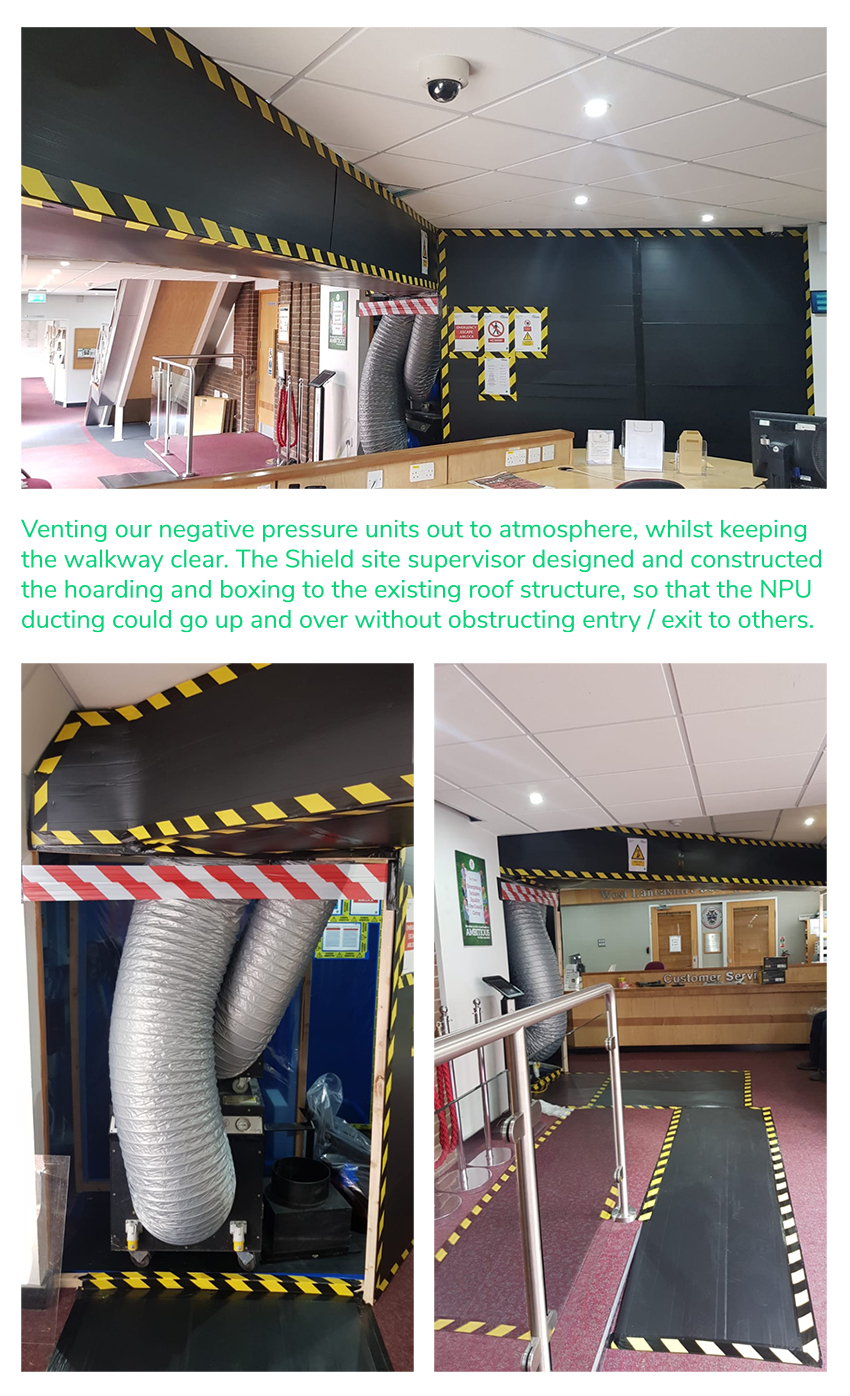

Working in a live environment brings many challenges and our team had to ensure that Health & Safety protocols were strictly adhered to. We were allocated our own site compound which was fenced off with a traffic gate. All transit and waste routes were clearly signed and sealed curing certain times and the decontamination unit (DCU) was also within the site compound.

Due to the space restrictions within the hallways, waste runs to the skip were undertaken at designated times throughout the day. Additionally, due to the congestion of the pipework, certain areas of the duct space were difficult to access. However, these areas were identified prior to the works started and were targeted first to allow emergency access routes to all areas of the duct space.

Our specialist teams used a number of removal techniques, including wet injection, wrap and cut, shadow vacuuming, suppressant and wire brushing, and all works were carried out in accordance with the Control of Asbestos Regulations 2012 (CAR2012), and the Licensed Contractors Guide HSG247.

As the work was being carried out in duct spacing, all gas was isolated and purged and the existing heating systems isolated and drained. Some specialist equipment was also required such as 4000 &1500 NPUS, gas monitors, tripod & winch, wet bulb, harnesses, wet injection machine and BA Sets.

To ensure that the works were completed efficiently and anyone else on-site was kept safe, the site supervisor and contracts manager had regular progress meetings with the client and the other sub-contractors that were on site.

Our team also worked alongside the heating sub-contractors to assist in breaking out of various locations within the duct, after the main works were completed.